Winter-Storage 2010/11

My trip to the Lesum combined the pleasant with the practical. Since Peter Wadephul's son ran a pleasure boat yard there, Emma was able to spend the winter break in a shed. Unfortunately, the crane only had an inaccurate scale, which had to be read from the ground with binoculars. It read somewhere between 3 and 3.5 tons – which matched my 'volume calculations'. Compared to the boat traverse of the Deutsche Industriewerke at Emma's maiden voyage, this pretty red-painted specimen seems almost a little small-chested. ;-)

After exploring the Lesum with Emma for a few weekends after my arrival, she was one of the first boats in the large boathouse. I lifted Emma's engine out of the boat with a forklift for a general overhaul. The forklift's tines and the engine fit easily between the roof and the coaming—a happy coincidence. With other boats, the engine must first be turned 90° in the boat so that it can fit through this narrow passage, which is of course inconvenient with an engine weight of around 200 kg.

Supported by a few beams and secured with two straps, the machine fits easily into the small BMW 3 Series. With a forklift and lifting straps, it was child's play. Luckily, I was able to unload it again with a forklift in Hanover – otherwise, it would have been just as easy as in Berlin with four friends and a few sturdy planks...

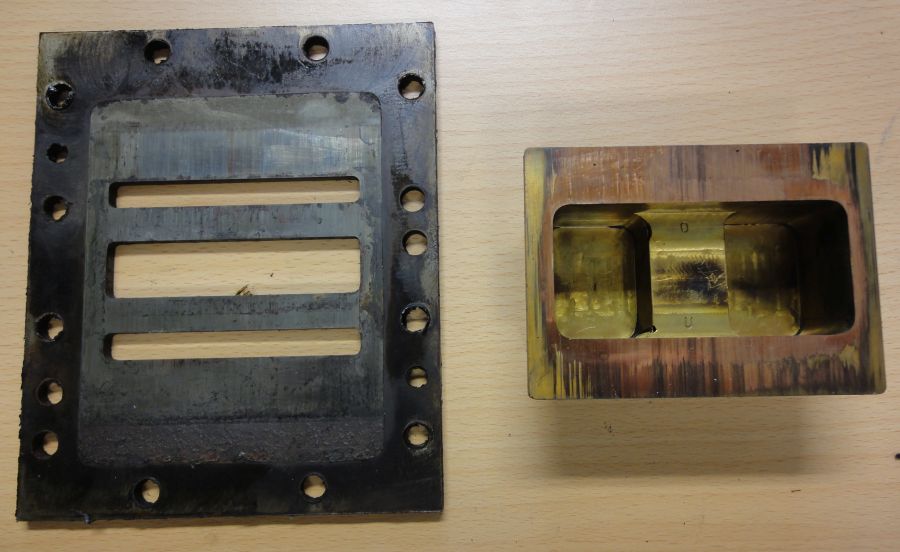

During the machine overhaul, my greatest interest was the low-pressure flat slide valve. The large sealing surface of the D-valve creates very high frictional forces. The risk of wear and scoring on the sealing surfaces of the slide plate (left in the photo) and the D-valve is correspondingly high. I was extremely surprised that neither surface showed any significant signs of wear. A light grinding with a hand-held grinding stone was enough to restore full sealing effectiveness. It was therefore worthwhile to manufacture the slide plate, which is bolted separately to the cylinder block, from tool steel, have it hardened, and then grind it flat.

Emma remained in the water continuously from early 2008 to late 2010, including two winters. When cleaned with a high-pressure washer, the minimal mussel and algae growth reliably detached from the thin-layer antifouling. At the grey spots visible in this photo, the high-pressure washer partially removed the antifouling. However, the underlying triple zinc-epoxy coating was completely intact at all points, so no further work was required. The effort of sandblasting the entire hull has clearly paid off.

In spring 2011, Emma shone in full glory again. I had long considered whether to cover the deck with wood and had left it grey-primed until this winter. Many boat owners reinforced my decision to keep the deck in its original form, with the painted diamond plate in the bow area. On the one hand, this preserves the authentic condition; on the other, a paint finish is significantly easier to maintain and makes the boat straightforward and practical for year-round use. Meanwhile, I switched from the very light „cream“ shade to a slightly more subdued „beige.“

The oak cabin structure was protected from the start with an open-pore paint, as used for windows and other dimensionally stable wood in construction. Only light sanding and repainting were needed here.

To give Emma a luxurious appearance, I had high-gloss varnished the roof edge, made of multiply laminated mahogany veneer, with two-component lacquer. I had to renew this finish as early as the winter of 2007/08, and I Repeated the process in 2010/11. Unfortunately, it became clear in subsequent years that even the smallest damage to the lacquer allowed water to penetrate, causing blisters in the finish. At the next opportunity, I removed all the clear lacquer and applied the open-pore paint from construction chemistry, which had already proven successful on the cabin wood, for weather protection.